Sales hotline: +1 800 878 3675

Corrosion Testing

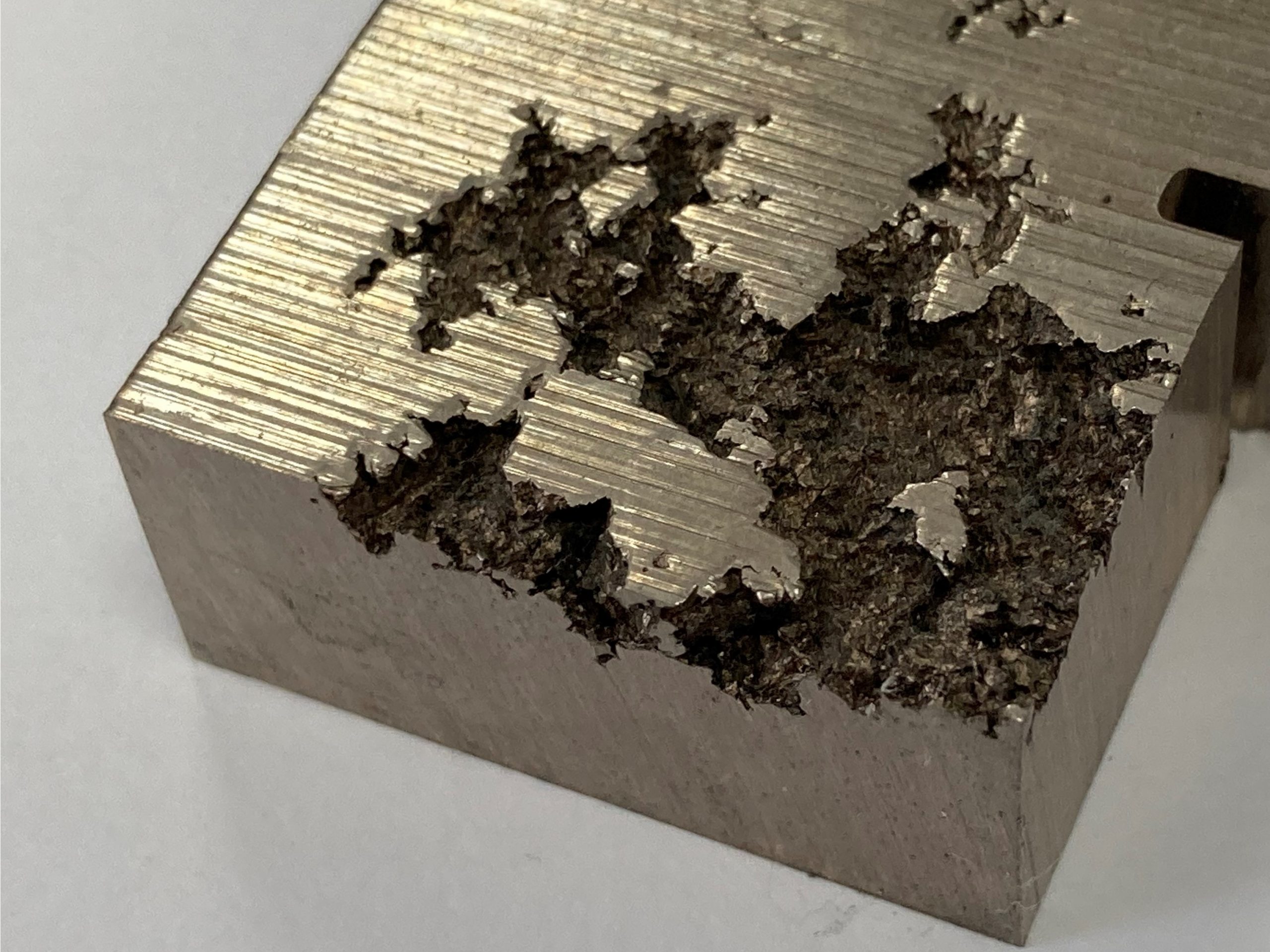

Corrosion tests are routinely undertaken during the production of metals. For instance, ASTM G48-A is undertaken as standard for duplex and super duplex stainless steels, as confirmation of their pitting and crevice corrosion resistance – ensuring their microstructure is well-balanced between austenitic and ferritic. Similarly, ASTM G28 is used with grades such as Alloy 625 and Alloy 825 to confirm their resistance to intergranular corrosion – which can occur if incorrectly heat treated – or ASTM A262 for austenitic stainless steels such as Alloy 316L.

Given the variety of corrosion tests, conditions, sampling regimes and test configurations, we are able to undertake additional testing as defined by customer and end user specifications. Our Technical team maintain records of customer specifications, allowing us to interpret their specific requirements and if stock items already meet. If not, product batches can be selected from stock, samples quickly taken and sent for testing locally, allowing us to meet your requirement in a timely manner.